Businesses often ask whether a steel bracket is better or an aluminum bracket. In response to this problem, the author here briefly analyzes the advantages and disadvantages of steel and aluminum.

1. Material strength

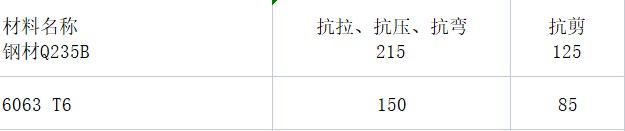

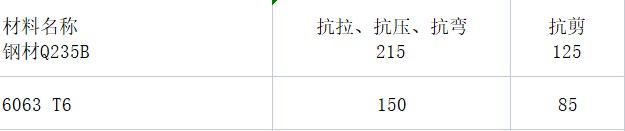

The bracket generally uses Q235B steel and aluminum alloy extruded profile 6063 T6. The design strength comparison between the two is shown in the following table:

Strength comparison table (N/mm2)

In terms of strength, 6063 T6 aluminum alloy is about 68%-69% of Q235 B steel. Therefore, steel is better than aluminum alloy profiles in areas with large spans and strong winds.

2. Deflection and deformation

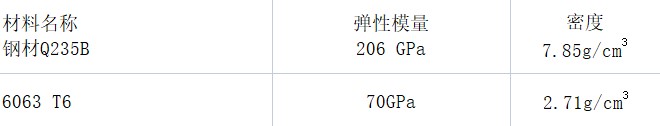

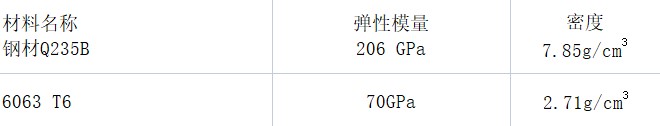

The flexural deformation of the structure is related to the shape and size of the profile, and the elastic modulus (intrinsic parameter of the material), but it is not directly related to the strength of the material.

Comprehensive comparison of the two under the same cross-sectional conditions

Under the same conditions, the deformation of aluminum alloy profile is 2.9 times that of steel, and its weight is 35% of steel. Under the same weight, the cost of aluminum profile is 3 times that of steel. Therefore, the cost of steel is better than aluminum alloy profiles in areas with strong winds and large spans.

3. Anti-corrosion aspect

At present, the main anti-corrosion methods for stents are hot-dip galvanizing of steel 55-80μm and anodic oxidation of aluminum alloy 5-10μm.

In the atmosphere, the aluminum alloy is in the passivation zone, and a dense oxide film is formed on the surface, which hinders the contact between the surface of the active aluminum matrix and the surrounding atmosphere, so it has very good corrosion resistance, and the corrosion rate decreases with time.

Under ordinary conditions (C1-C4 environment), 80μm galvanized thickness can be used for more than 20 years. However, in high-humidity industrial areas, high-salinity seashores and even temperate seawater, the corrosion rate is accelerated, the amount of galvanization needs to be more than 100μm, and regular maintenance is required every year.

Aluminum alloy is far superior to steel in terms of corrosion protection.

4.other aspects of comparison

(1) Appearance: There are many kinds of surface treatments for aluminum alloy profiles, such as anodizing, chemical polishing, fluorocarbon spraying, electrophoretic coating, etc. Beautiful appearance, can adapt to various corrosive environments.

Steel is generally hot-dip galvanized, steel sprayed, and painted. The appearance is not as good as aluminum alloy profiles. Its corrosion resistance is not as good as aluminum profiles.

(2) Cross-section diversity: The general processing methods of aluminum alloy profiles include extrusion, casting, bending, and stamping. Extrusion production is currently the mainstream production method. By opening the extrusion die, any profile of any cross section can be produced, and the production speed is relatively fast. Steel generally adopts rolling, casting, bending, and stamping. At present, rolling is the mainstream production method of cold-formed steel. The section needs to be adjusted by a roller set, but the general machine can only produce similar products after sizing. The size can be adjusted, but the section shape cannot be changed. For example, the section of C-shaped steel and Z-shaped steel. The rolling production method is relatively fixed and the production speed is relatively fast.

5.comprehensive performance comparison

(1) Aluminum alloy profiles are light in weight, beautiful in appearance, and excellent in corrosion resistance. They are generally used in roof power stations with load-bearing requirements and strong corrosive environments. For example, in the power station of a chemical plant, it is better to use aluminum alloy as the support.

(2) The strong height of steel has small deflection and deformation under load, and it is generally used for power stations or components with relatively high stress.

(3) Cost: Generally, the basic wind pressure is 0.6kN/m2, the span is less than 2m, and the cost of the aluminum alloy bracket is 1.3-1.5 times that of the steel structure bracket. In small-span systems (such as color steel roofs), the cost difference between aluminum alloy brackets and steel structure brackets is relatively small, and aluminum alloy brackets are much lighter than steel brackets, which are very suitable for rooftop power stations.