Tech Explained|A "Limit Test" Report for a Mounting System

The "intrinsic quality" of a mounting system is often hidden beneath the surface—encompassing material selection, manufacturing process implementation, and the assessment of anti-corrosion grades.

Material: Determining Performance

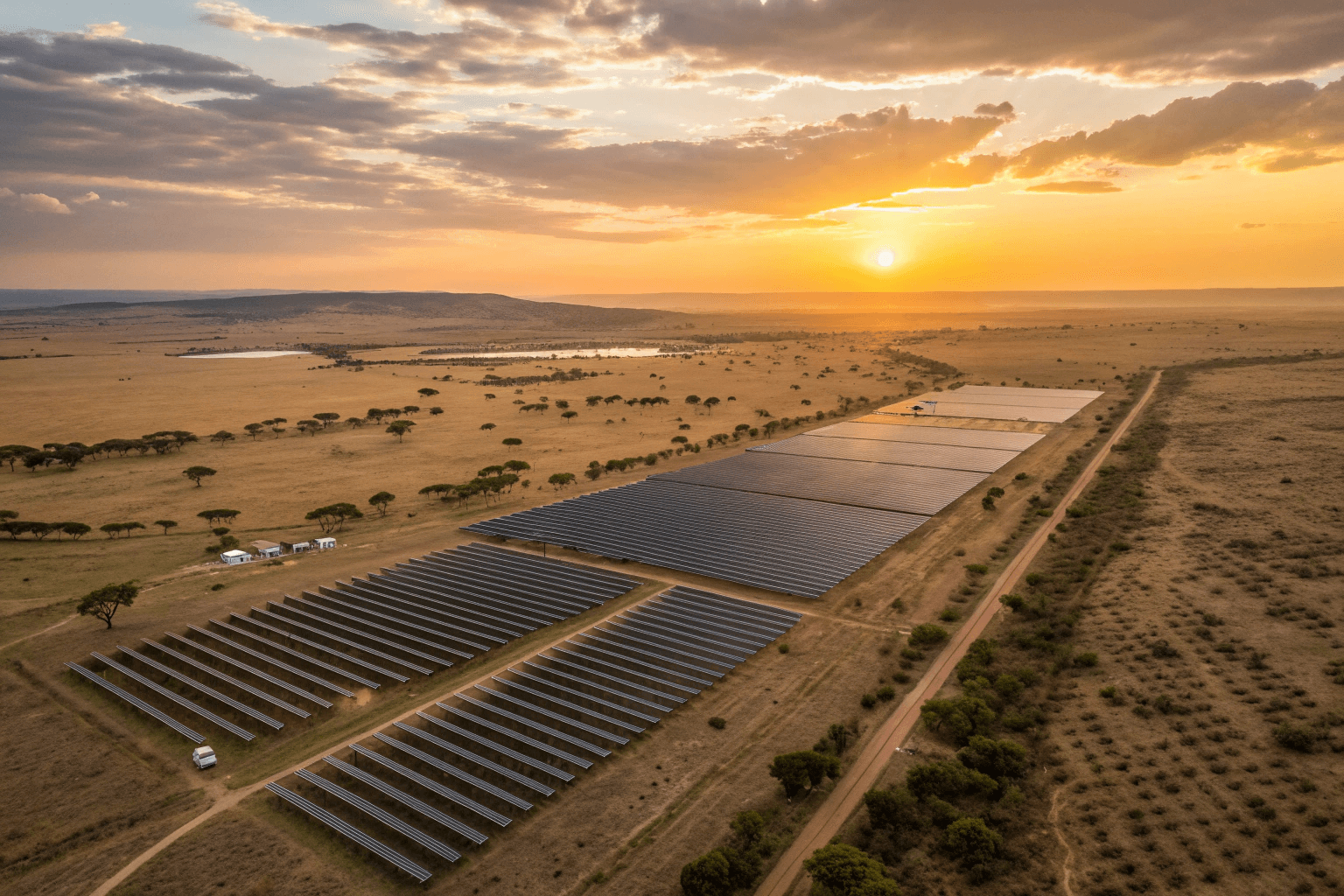

The material choice for photovoltaic mounting systems directly impacts their strength, durability, and suitability for application scenarios. Currently, mainstream materials in the market primarily include steel, aluminum alloy, and new composite materials. Steel, with its excellent strength and relatively economical cost, dominates in large-scale ground-mounted power plants. Among these, galvanized steel further enhances weather resistance through surface treatment. Aluminum alloy mounting systems showcase unique appeal in rooftop distributed PV and BIPV applications due to their light weight, corrosion resistance, and ease of processing. Although their strength is generally lower than steel and their cost is typically higher, they offer irreplaceable value in reducing building load and simplifying installation.

Process: The Key to Quality

If material is the foundation, then the manufacturing process is the soul that transforms materials into reliable products. The manufacturing processes for PV mounting systems are diverse, with connection techniques directly affecting structural integrity and stability. Among mainstream connection methods, welding primarily focuses on reliability and structural stability. In scenarios requiring flexible adjustment or disassembly, bolted connections are widely adopted for their ease of installation and adjustment. In this field, Grace Solar consistently drives technological innovation, utilizing advanced process technologies to ensure connection structures maintain excellent overall performance and long-term reliability under various environmental conditions.

Anti-corrosion: Ensuring Long-term Service

Anti-corrosion grade is a core indicator for evaluating the durability of PV mounting systems, reflected through systematic testing standards and certification systems. Internationally recognized standards such as ISO 12944, ASTM, and GB/T define protection level requirements for different corrosive environments. In practical assessment, alongside laboratory accelerated testing methods, emphasis is also placed on long-term field tracking and validation in actual outdoor environments. Effective anti-corrosion is a systematic project spanning design, material selection, manufacturing, and even long-term maintenance, requiring coordinated advancement from various aspects like structural optimization and detail handling to ensure lasting and stable protective effects.

As PV application scenarios continue to expand, Grace Solar will continue to deepen innovation in mounting system technology, driving product evolution towards intelligence, lightweight design, and high weather resistance, making green energy safer, more efficient, and more durable in illuminating the future.

.jpg)