Tech Explained | PV Mounting Systems: The "Invisible Guardians" Behind Power Plant O&M

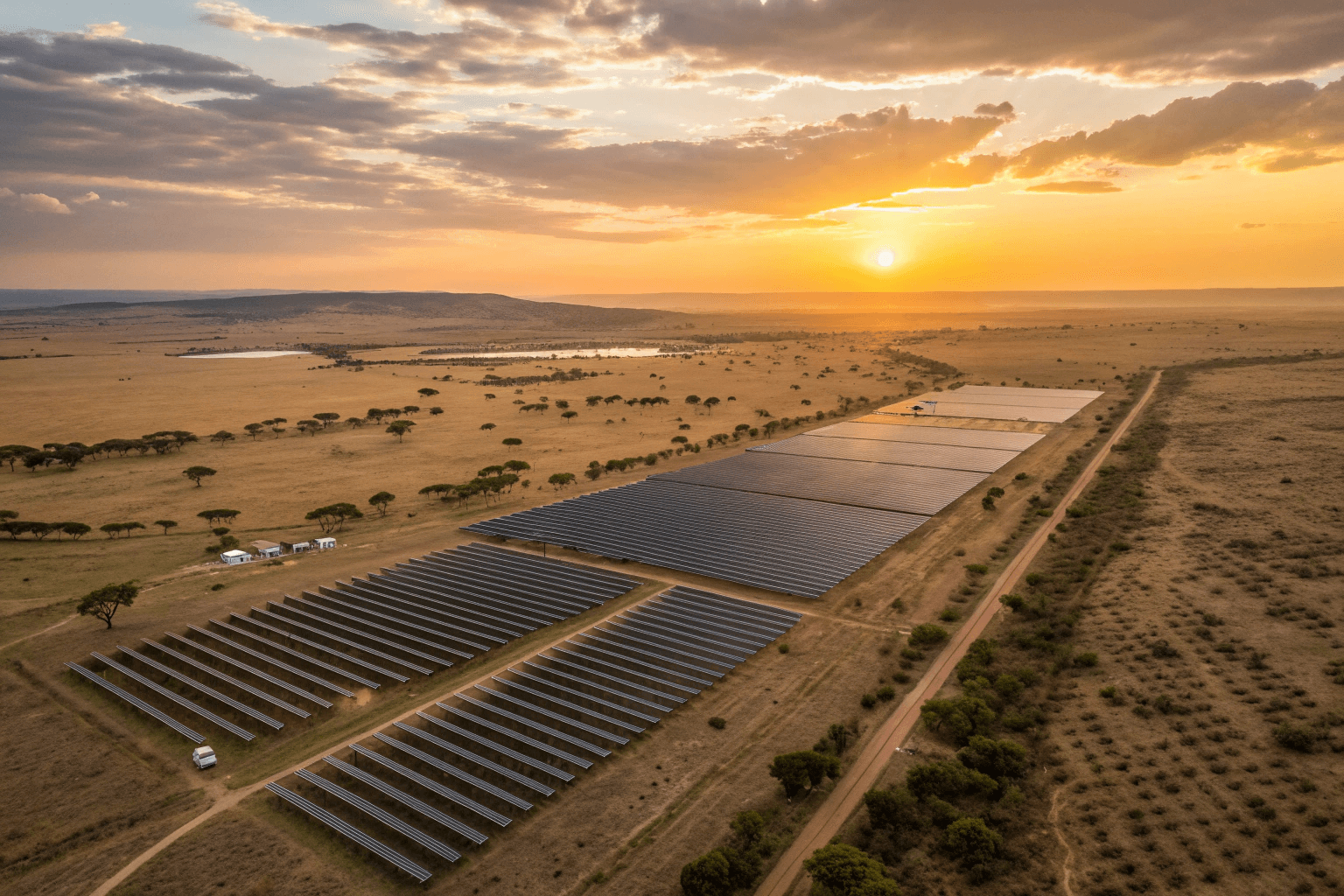

In the operation and maintenance (O&M) of photovoltaic (PV) power plants, while attention is often drawn to the gleaming solar panels and sophisticated inverters, few notice the silent steel structures that support the entire system. These metal frameworks, which may seem simple at first glance, are actually the cornerstone for long - term stable operation.

Take GraceSolar’s smart tracking system as an example: its AI - driven real - time tilt optimization has the ability to boost power generation by 15% - 30%, redefining the traditional concept that "mounting systems are merely support structures."

According to the latest report from the International Energy Agency (IEA), the average amount of global power generation losses caused by mounting system problems reaches 3.7%, and can even reach 8% in harsh environments. This underestimated figure reminds us to reevaluate the strategic importance of mounting systems in the PV ecosystem.

"Mounting Systems: The "Barometer" of Plant Health

Although PV mounting systems have evolved into intelligent solutions integrating mechanical engineering, materials science, and IoT technology, most current systems still prioritize structural stability and cost-effectiveness. O&M teams rely on the following basic health monitoring methods:

?Periodic bolt torque rechecks (using standard torque wrenches, covering the entire plant quarterly).

Visual inspections for foundation settlement (with simple level gauges, error threshold set at ±3 cm).

Manual corrosion checks on steel structures (focusing on welds and connectors before and after rainy seasons).

A cautionary case from a 200 MW Southeast Asian power plant highlights the consequences of neglecting a 5 cm foundation settlement, which triggered a chain reaction leading to misaligned arrays, an annual power loss of 5.2%, and direct financial losses exceeding $1.2 million.

Environmental Adaptability: Tailored Protection Strategies

In a desert plant in Dubai, the O&M team developed a "dust index-cleaning cycle" algorithm to predict optimal rail maintenance timing based on weather data. Meanwhile, at an offshore PV project in China’s East China Sea, engineers innovated with graphene-based anti-corrosion coatings, extending maintenance intervals from 3 to 18 months. These practices are redefining O&M standards for mounting systems.

GraceSolar adopts cost-effective adaptive solutions for different environments:

High-Salt Coastal Zones:?Two-component epoxy resin coatings + annual comprehensive anti-corrosion inspections.

Permafrost Zones:?Deep-pile foundation designs (buried 1.5 meters below the frost line).

Lean O&M: Optimizing Traditional Techniques

Industry research shows that simply strengthening manual inspection protocols and preventive maintenance can reduce sudden failures by over 30%. As noted in an IEA report: "The potential of traditional mounting systems remains underutilized; systematic O&M management can deliver significant efficiency gains."

As the PV industry advances toward high-quality development, GraceSolar’s mounting systems—with their solid engineering foundation and continuous O&M improvements—silently ensure plant stability. This underscores a simple truth: The most reliable technology isn’t always the most cutting-edge, but the most suited to the current stage of development.

.jpg)