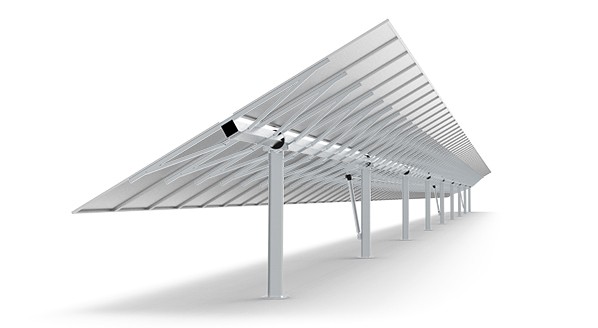

GS-Light Intelligent Tracking System Solution

Multipoint Drive 2P

Enquiry Now

Solution Intro

Self-developed unique and highly reliable multi-point transmission tracking structure system, large torque tube, structure rigidity increased by 20%, can resist greater wind resistance, each row of trackers has 2 or more drivers, which is more improved accurate tracking accuracy and structural reliability, using the most advanced wind tunnel design, can adapt to multi- angle protection strategies, specifically designed for 182mm and 210mm large silicon high- power components.

Features

-

Two artificial intelligence

-

AI control

-

Reliable and safe communication

-

Extreme weather protection

-

Wind tunnel test report

-

600W+ Module

-

Match module length up to 2.5m

-

Reducing LCOE cost

-

Improving the efficiency by 15-25%

Application

It is suitable for various power plant projects,especially in power plants with double-sided modules or high civilconstruction costs

Technical Specs

Features

● 3 single-row drive devices, can improve the structural rigidity of the system and the system has stronger wind resistance

● Adopt advanced AI intelligence and double-sided tracking algorithm, higher power generation

● The column span is larger, the number of installed machines is less, and the construction cost is greatly reduced

● Forward-looking design, applicable to 182mm and 210mm large silicon wafer high-power components, with a maximum of 120 components

● Differentiated column design, different pile foundations can be selected according to different geological conditions, the slope of 15% in the north and south can be realized, and the slope in the east- west direction is unlimited;

● The system has passed third-party testing and certification such as wind tunnel and TUV to ensure stable operation of the system for 25 years;

● It can be matched with AC or PV power supply to improve the stability of wireless transmission, take into account the laying of string and tracking cables, and greatly reduce the cost per kilowatt-hour (LCOE) of the power station.

● Adopt advanced AI intelligence and double-sided tracking algorithm, higher power generation

● The column span is larger, the number of installed machines is less, and the construction cost is greatly reduced

● Forward-looking design, applicable to 182mm and 210mm large silicon wafer high-power components, with a maximum of 120 components

● Differentiated column design, different pile foundations can be selected according to different geological conditions, the slope of 15% in the north and south can be realized, and the slope in the east- west direction is unlimited;

● The system has passed third-party testing and certification such as wind tunnel and TUV to ensure stable operation of the system for 25 years;

● It can be matched with AC or PV power supply to improve the stability of wireless transmission, take into account the laying of string and tracking cables, and greatly reduce the cost per kilowatt-hour (LCOE) of the power station.

Mechanical Aspect

|

Number

of tracker drive modules |

2X60 |

Material |

Hot-dip galvanized steel + aluminum-magnesium-zinc plate + pre-galvanized |

|

Number of motors per tracker |

3-5 |

North-south land slope |

<15% |

|

Tracking range |

±50° |

Module arrangement |

Double row vertical |

|

East-west land slope |

Unlimited |

Foundation form |

Static pressure pile, cement precast pile, concrete foundation |

|

Mechanical tracking accuracy |

±2° |

Standard

wind speed |

<47m/s,3seconds

gust, (customizable) |

|

Protection wind speed |

18m/s |

Ground clearance |

>500mm,(customizable) |

|

Land

occupation rate |

30% |

Grounding

method |

Self-grounding |

Electrical Aspect

|

Drive

way |

Linear actuator drive |

Motor protection |

Overheat

protection, overcurrent protection, self-locking protection |

|

Motor Power |

220W |

Limit protection |

Mechanical limit + motor hard limit + soft limit |

|

Flat

time |

<8 minutes |

Control mode |

Independent GPS time control + tilt sensor hybrid control |

|

Controller |

MCU |

Power consumption |

< 0.05kWh/day |

|

Control tracking accuracy |

<2° |

Power supply |

String

power supply/external power supply |

|

Protection level |

IP65 |

Communication method |

LoRa/Zigbee wireless communication or RS485 |

|

Operating temperature |

-40-+70℃ |

Signal transmission method |

Wired/wireless

optional |

产品图 (1)(2).jpg)